The story of Coriolis Composites is built on a passion shared by the founders with all employees who have gradually joined the ranks of this industrial adventure. These highly qualified, multidisciplinary and multilingual experts are a major asset of the company and are all committed to delivering exceptional customer satisfaction.

A STARTUP STORY IN THE INDUSTRY

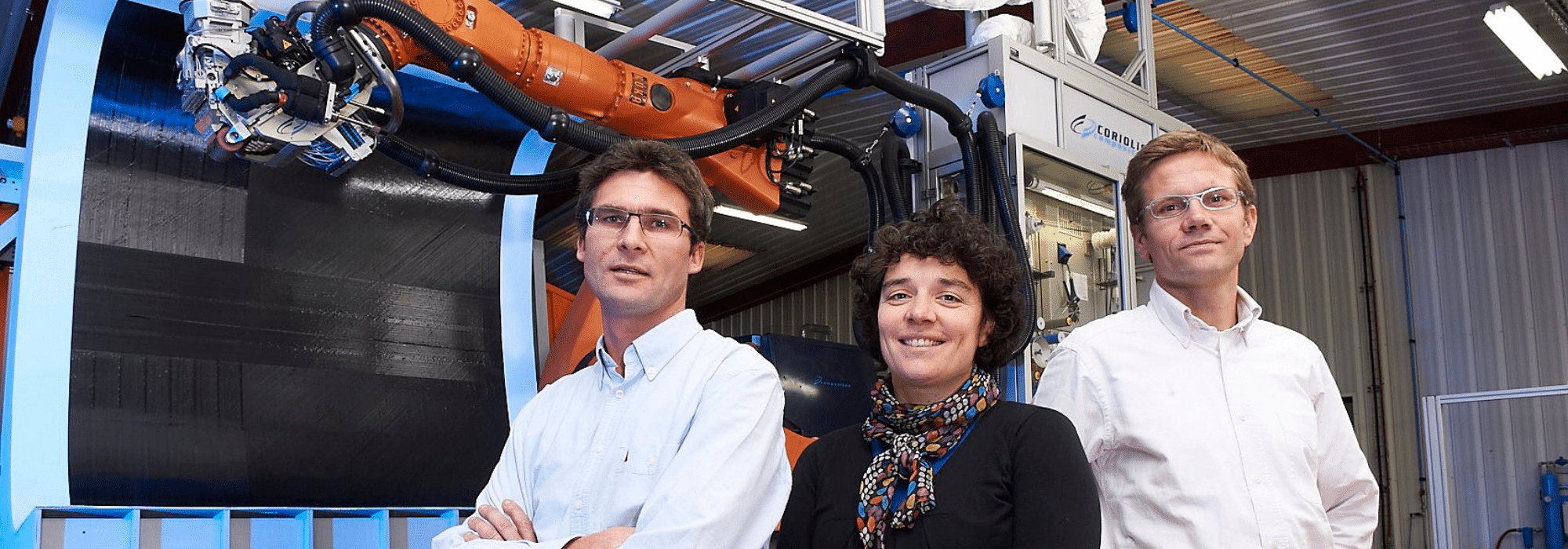

The idea of Coriolis Composites was born in 1996, well before its founders, Clémentine Gallet and Alexandre Hamlyn, graduated from the engineering school. It is a real entrepreneurial adventure that has gone through all stages of development, including mountains to climb, arbitrations, phased deployment and finally, a genuine growth to become the flagship of the French composite industry.

ADAPTING TO CUSTOMER’S NEEDS

Creating a company means also knowing how to reorient a business model. This is what they refer as their second mountain to climb. They had the patents, the robots, but not their first client. Ultimately, it was their ability to adapt, as well as their persuasiveness, that enabled the sale of their first AFP machine to Airbus, which also meant changing their offer.

FROM THE IDEA TO ITS REALIZATION

With their sidekick Yvan Hardy, the two students, without having earned their first Euro, were convinced that their idea could revolutionize a nautical industry, which was reliant on the lightness of the composites, but the manual processes of which, left room for their ingenuity.

Their project was appealing, and they soon benefitted from various grants, including the ANVAR support, material loans, access to laboratories in France and Germany allowing them to make the first prototypes and file for their first patents. They finally seduced the French Ministry of Research who consequently validated their market research study. Following a number of fund-raising attempts, their project was finally brought to life thanks to the support of the regional development fund of Brittany (France).

The Coriolis Composites was created and registered in Lorient in 2000 and is still today a privately-owned company.

EXPORT AND GROWTH

Having successfully climbed the three mountains, Coriolis Composites is now looking into the future and concentrates on growing as a business. As a pioneer in the adoption of robotics for materials and processes, Coriolis Composites is now emerging in new industrial markets such as the automotive industry, and new export markets in the United States and Asia.

It is also preparing for the industry of the future by mastering additive technologies, recyclable thermoplastic materials and the connected factory software.

TRANSFORMATION & INDUSTRIALIZATION

After Coriolis Composites had sold its first machine, it had to produce more in order to reassure its customers in a sector where certifications are complex and extremely demanding. It was no longer a question of conducting research but flying a plane !

The company also had to ensure recurring revenues to enable its sustainability. In 2010, Coriolis AFP cells manufactured the first nacelles for Safran. And in 2014, it produced the first structural parts for Airbus. Now, carbon can fly in constrained parts. This helped to convince the US market. The initial passion was turned into an industrial innovation with the development of a catalogue of standard and modular fiber placement robotic cells.

BUILDING ON THE TEAM

The story of Coriolis Composites is built on a passion shared by the founders with all employees who have gradually joined the ranks of this industrial adventure. These highly qualified, multidisciplinary and multilingual experts are a major asset of the company and are all committed to delivering exceptional customer satisfaction.